FEA Analysis

FEA Analysis Through Scanning Technologies:-

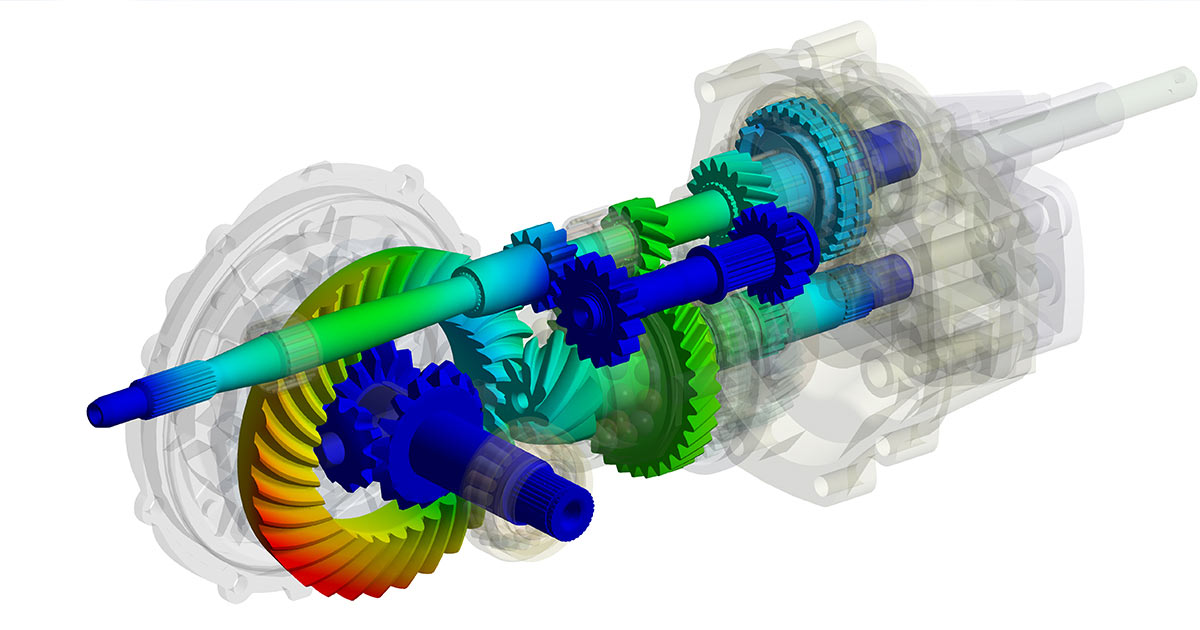

Finite Element Analysis (FEA) combined with 3D scanning technologies enhances structural analysis, material testing, and performance evaluation of components. This approach helps engineers identify stress points, optimize designs, and improve product durability before manufacturing.

Key Aspects:

- Accurate 3D Model Creation – 3D scanning captures real-world object geometry with high precision.

- Mesh Generation for Simulation – Scanned data is converted into a fine mesh for FEA simulations.

- Stress & Strain Analysis – Helps evaluate mechanical performance under various load conditions.

- Material Property Integration – Enables realistic simulations by applying actual material characteristics.

- Optimization of Design & Performance – Identifies weak areas and suggests design improvements.

- Failure Prediction – Detects potential cracks, deformations, or structural failures in components.

- Reverse Engineering Applications – Allows re-analysis and validation of legacy parts for better durability.

- Time & Cost Efficiency – Reduces the need for physical prototypes, saving production costs.

- Multi-Industry Application – Used in automotive, aerospace, medical, and industrial machinery for performance validation.

- Enhanced Manufacturing Accuracy – Ensures products meet quality and safety standards before final production.

- By integrating 3D scanning with FEA, companies can streamline design processes, improve product reliability, and reduce development time, making it a crucial tool for modern engineering analysis. 🚀